What is Steel Frame & CLC

Construction technique with a lightweight steel frame load bearing structure, walls cladding with light slabs and FOAM CONCRETE (CLC) filling.

The COISOIMPER offer with Steel Frame system.

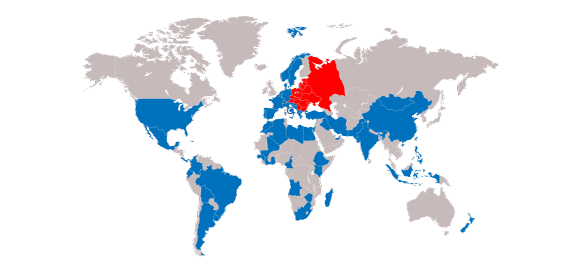

COISOIMPER offers, in Italy and around the world, a combination of construction technology with the lightweight steel frame load bearing structure (Steel Frame System) and FOAM CONCRETE (CLC).

Self-produced Slabs in FOAM CONCRETE (SLABS HP) with high strength and flexibility are used as formwork for low density casting.

The resulting structure is a single body with box-like behaviour, without seams, connections or fastenings. COISOIMPER can perform feasibility studies that are compatible with the most diverse needs and aesthetic and structural characteristics in use in the relative places or countries. Filling with low density cellular concrete (300 kg/m3 – 0.075 Lambda) makes the wall insulating and reinforces the structure.

What is the best way of using Steel Frame with FOAM CONCRETE (CLC)?

– With the application of high strength and flexibility FOAM CONCRETE slabs (SLABS HP) and low density FOAM CONCRETE casting.

The slabs are self-produced in factory with customised measurements and weight, using local raw materials and labour.

– With the application of fiber cement slabs or similar, which can be found on the local market, and low density FOAM CONCRETE (CLC) casting.

The filling of FOAM CONCRETE walls makes the building walls resistant to impact and wall-mounted units.

What is the Steel Frame & CLC construction technique?

A new technology to build residential, commercial or industrial structures.

Steel Frame is a new technology where the load bearing structure, the floors and the supporting structures are built with cold bent galvanised steel profiles, that make it possible to achieve any type of construction: residential, commercial or industrial.

The structure of the building is a seamless single body and is better able to withstand earthquakes than more rigid structures. In case of high intensity earthquakes, Steel Frame systems offer a high level of tolerance and also limit possible damage to the non-structural components.

As the cladding for roofs, floors and walls, cellular concrete helps keep the system perfectly together, keeping the structure lightweight while increasing the insulating characteristics and keeping costs low.

When to use Steel Frame & CLC?

The Steel Frame construction system is perfect for building single-storey and multi-storey monolithic homes.

The entire building is made with a steel structure filled with cellular concrete that increases the stability without increasing the weight.

How to make Steel Frame & CLC?

Building and cladding with assembly.

Building a Steel Frame house starts with the assembly of the steel profiles (i.e. the Steel Frame) which guarantees a reduced risk of error.

The steel profiles of the Steel Frame can be pre-assembled in factory or assembled directly on site.

When the structure is finished, the cladding is installed with FOAM CONCRETE (CLC) or fiber cement slabs and the electrical and hydraulic systems.

Then the walls are filled with low density CLC (300- 4000 Kg/m³) using suitable machinery such as the KOMPATTO or K250 series.

Machinery for building with the Steel Frame & CLC method.

– Rool Forming Machine

– PLM CLC slabs HP

– KOMPATTO or K250 (the entire series)

What are the advantages of Steel Frame & CLC?

Building with the Steel Frame method offers numerous advantages in every phase.

In the production phase:

– Low energy consumption

– Reuse of production waste

– Speed. 600 m/h of steel profiles and 160 m2/h of CLC slabs HP

– Flexibility for the design of the house

In the transport phase:

– It can be produced directly on site

– Reduced production costs

In the construction site:

– Quick construction. The construction times can be three time quicker

– Filling casting and on-site self-production of slabs, with local raw materials and labour

– Faster casting in comparison to the application of common fibre glass

– Environmental sustainability (less waste on-site)

– Excellent quality/price ratio

– No cranes, formwork, skilled labour

At the end of construction:

– Excellent thermal and acoustic insulation

– Fire resistance

– Energy savings

– Considerable mechanical strength

– Tearing strength for unit mounting

– Impact resistance

– Savings of up to 30% for domestic heating and cooling

– No need for insulating plaster

– Life long-lasting and safe

– Seismic-proof (the ductility and lightweight of the steel make the structure of the construction more resistance to earthquakes).

CLC SLABS HP

Request info

Contacts

Via Cassia zona ind.le Cesa

52047 Marciano della Chiana (AR)

Tel. +39.0575.842525

Fax. +39.0575.842800

info@coisoimper.com

CO.ISO.IMPER S.R.L. - Via Cassia, 52047 Marciano della Chiana (AR) - P.IVA 01275220513 - REA AR-94793 - Cap. Soc. 20.000,00 €

Copyright © 2024 | All rights reserved